Brushing and treatment lines are very useful machines in the manufacturing industry to achieve precise and uniform finishing on pieces. These machines are designed to brush and treat a wide variety of materials, including quartz, marble, metal, and other materials. In this article, we will talk about brushing and treatment lines, how they work, and the benefits they offer.

How do brushing and treatment lines work?

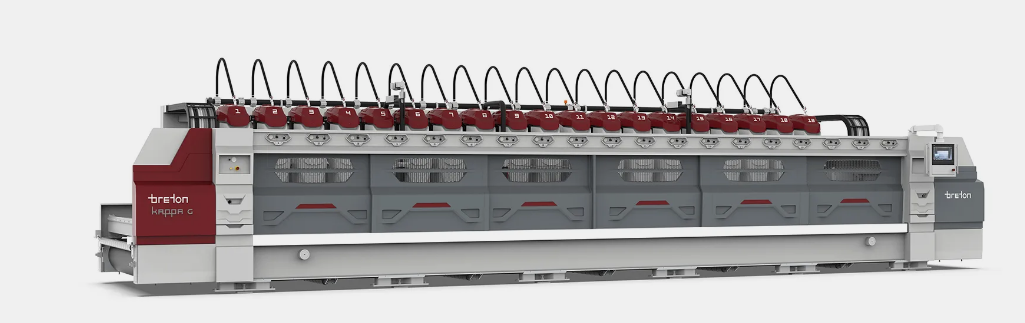

Brushing or polishing lines are machines used to polish and shine surfaces. These machines work by using rotating disks or brushes with different degrees of abrasion to achieve the desired finish. The disks can be made of different materials, such as resin, ceramic, or diamond, and can vary in size and hardness. Polishers work through friction and heat generated by the polishing disks and/or brushes on the surface being treated.

After brushing, the piece can be passed to a treatment machine that uses different techniques to create different finishes. For example, a treatment machine may use sandblasting to create a rough texture or use a special finishing technique to create a glossy finish.

Benefits of brushing and treatment lines

Brushing and polishing lines offer the following benefits:

- Improved finish quality: Brushing and treatment lines are very effective at improving the finishing quality of pieces. By removing any imperfections and creating a smooth and uniform surface, brushing and treatment lines help achieve high-quality finishes.

- Increased production process efficiency: Using brushing and treatment lines can significantly improve the efficiency of the production process. By using a series of machines designed to work together, a smooth and uninterrupted process is achieved, resulting in increased efficiency and cost reduction.

- Versatility: Brushing and treatment lines are very versatile, as they can be used on a wide variety of materials. This makes them very useful tools for the manufacturing industry, which needs to process different types of materials.

Cepicat is compatible with polishing lines

Brushing and treatment lines are very useful tools for achieving precise and high-quality finishes on pieces. Removing imperfections and creating smooth and uniform surfaces are two of the most common applications of these tools. As we mentioned earlier, abrasive disks and brushes are needed to perform the finishes. At Cepicat, we have been producing brushes for polishing metal and stone since 2005. You can check out our Cepimet and stone lines, where you will find high-quality brushes ideal for your polishing and treatment line. Our disks and brushes are compatible with all polishing brands.