Quienes Somos

“In the last decade CEPICAT has experienced constant growth in experience and sales volume, we are operating in more than 40 countries.”

CEPICAT was founded in 2005 with the aim of being a reference in modern brush production. Since the beginning of the activity we have placed special focus on the manufacture of high quality brushes with modern systems, machinery and production processes as well as the development of innovative products.

Products

Sectors for which we produce

We manufacture many standard products for the deburring and finishing machines that are on the market, as well as products tailored to the customer. We work with sectors such as automotive, aeronautics, construction, etc.

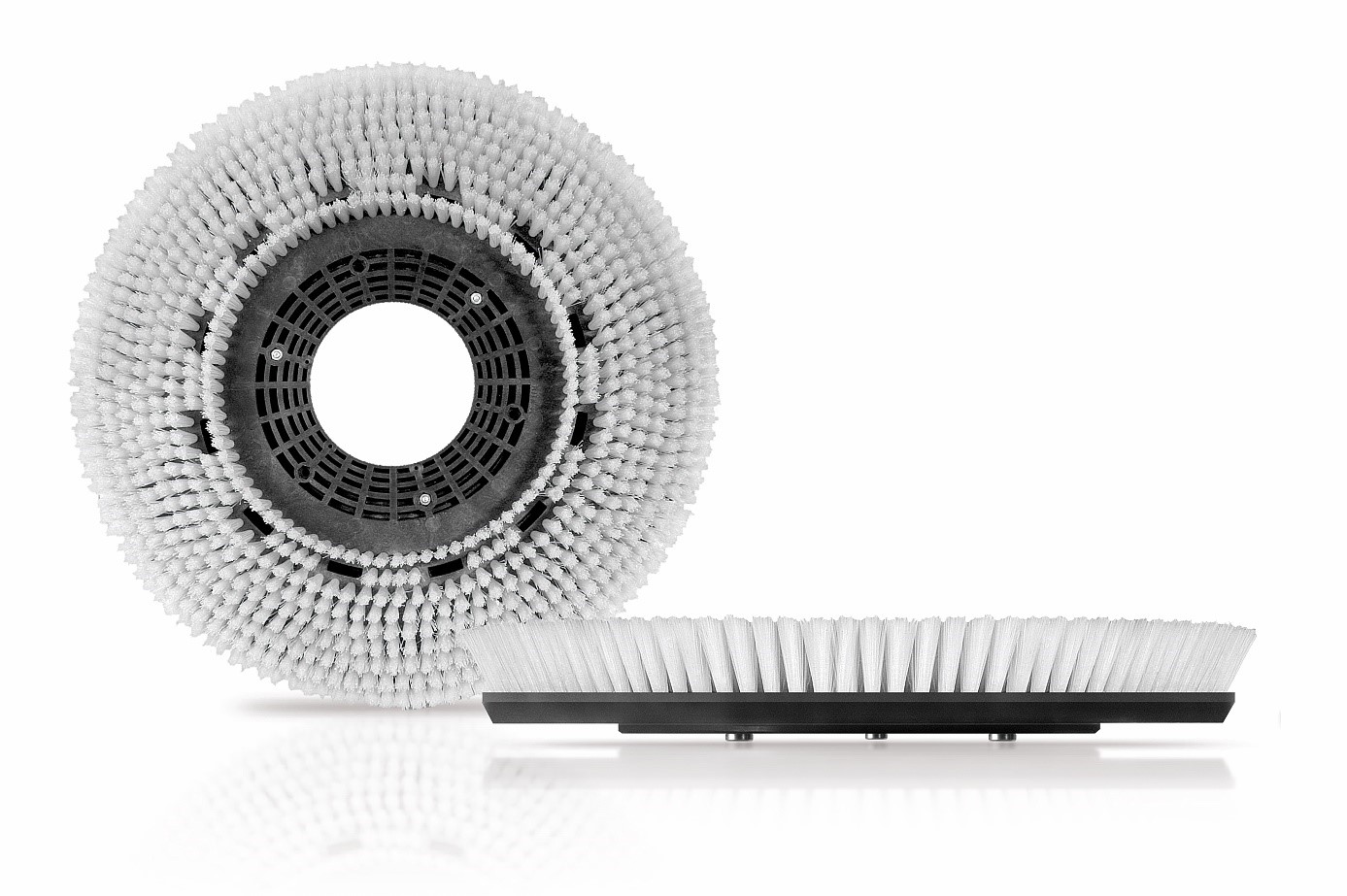

Floor Cleaning

Cleanliness is a key factor for customer satisfaction, employee safety and a pleasant working, selling and visiting environment. Requirements of clean floors are more and more present all over the world, especially in places with big quantities of people. CEPICLEAN is your partner for achieving best cleaning results.

Metal deburring

In metal industry, are a common and recurring problem. Abrasive brushes are used for an efficient und precise deburring of metal parts.

Our brushes are especially used in 2 areas; CEPIMET in the deburring of flat parts and casted parts, and CEPIWHEEL in the deburring af aluminium rims.

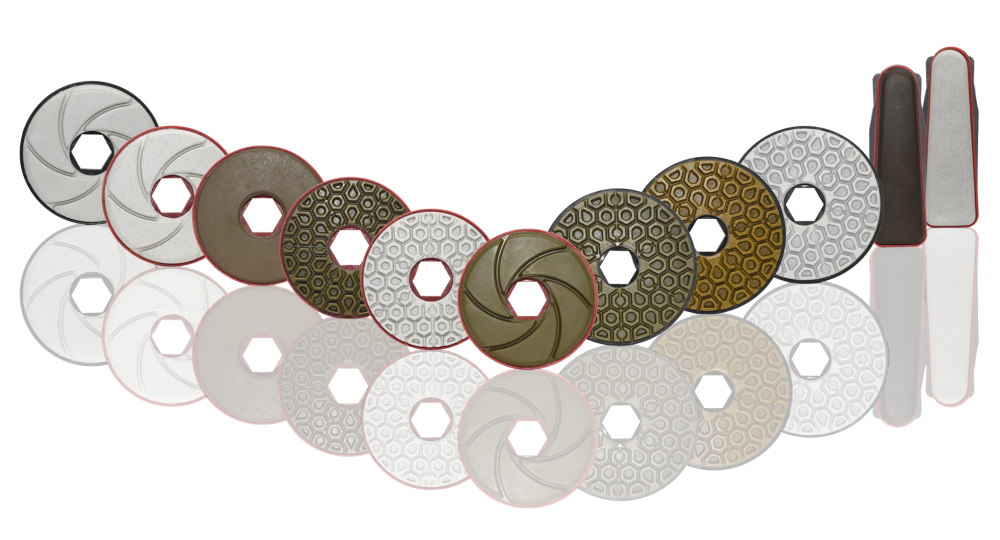

Quartz surfaces

El aglomerado de cuarzo es más blando que la cerámica y los abrasivos son menos agresivos. Actualmente, conseguimos acabados combinando abrasivos tradicionales con nuestros productos de goma CEPIFLEX.

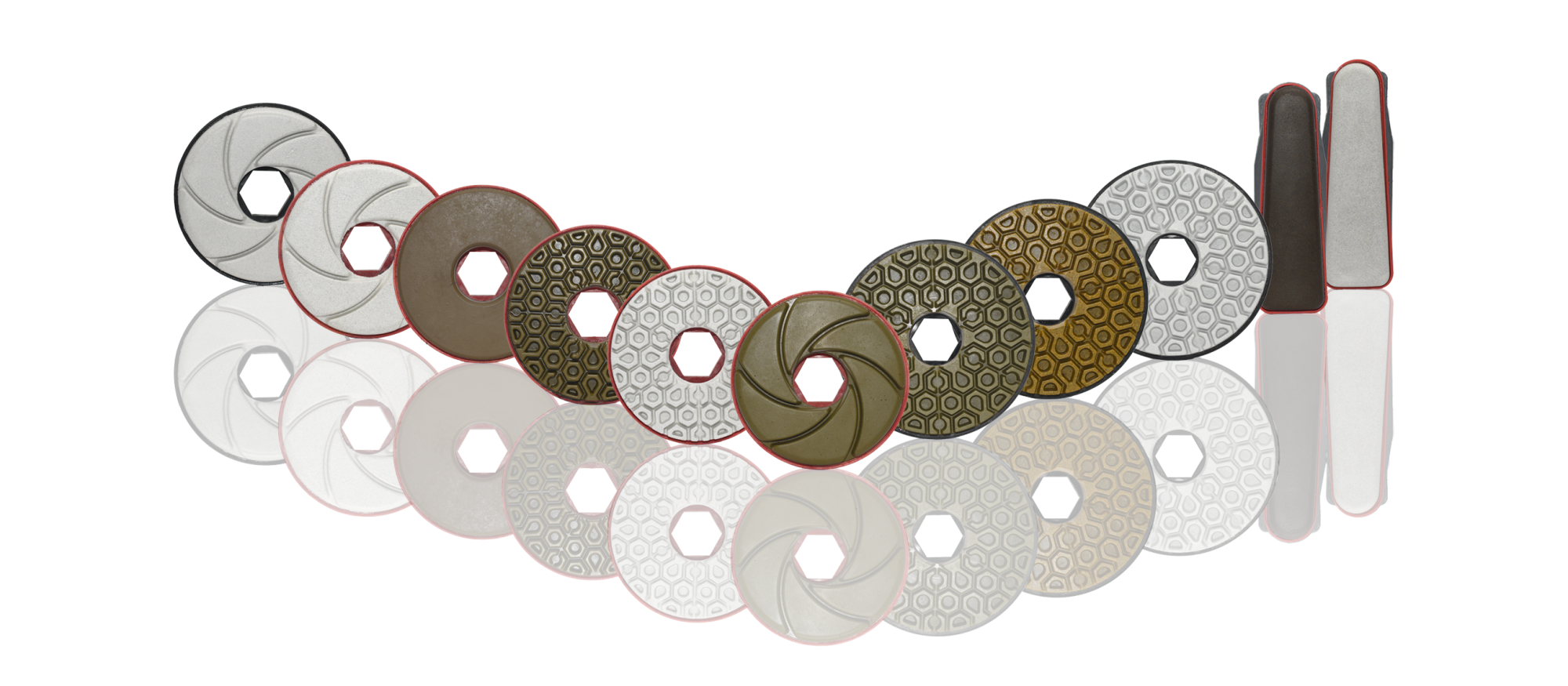

Stone Floor Renovation

Stone Flooring is elegant and trendy. Over time stone floors lose their appeal, due to scratches, stains and dirt. With our CEPIRENOVA-System your floors shine like new.

CEPIRENOVA is a simple and cost-efficient solution for the treatment of natural and artificial stone.

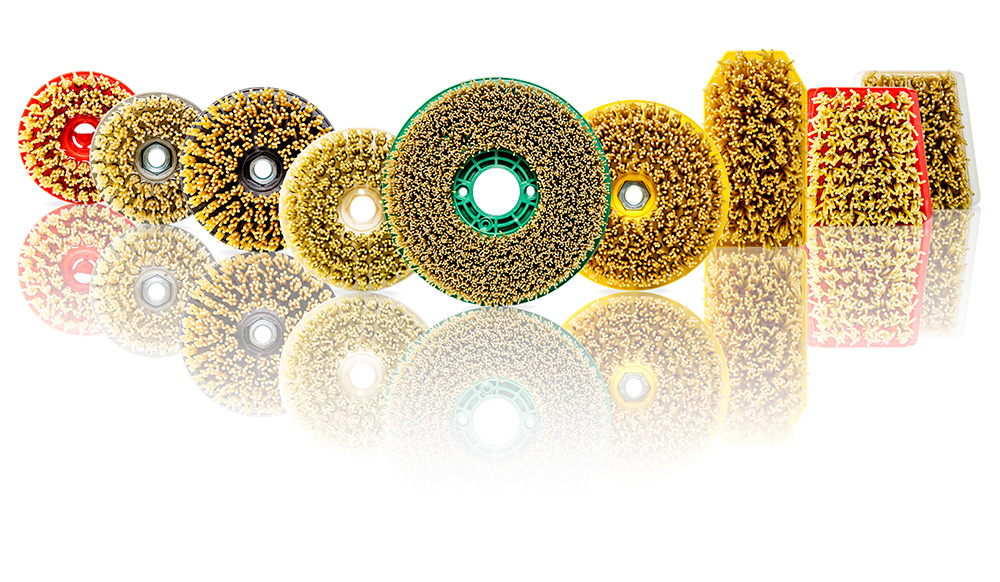

Ceramic

The “Satin” effect, our brushes made of carbide, diamond and ceramics are used. Or “Mate” which has a very low glaze levels, which we achieve by combining.

The ceramic market demands products with low glaze levels with perfect finishes that do not show any sign of the abrasives and that are produced with an anti-stain

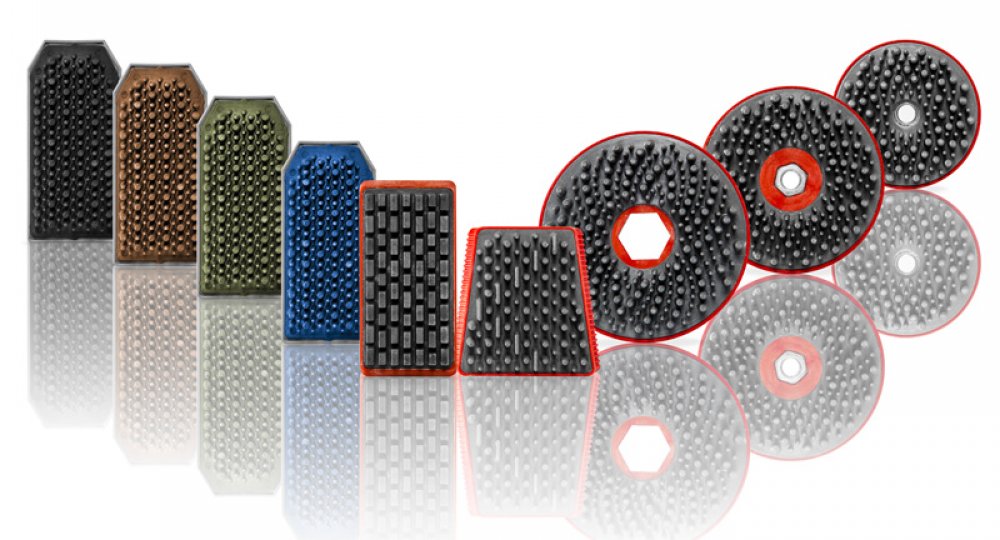

Stone

Aged effect

We manufacture abrasive nylon brushes to give the marble and granite texture. The bristles of these can be silicon carbide, aluminum oxide, diamond and among others an abrasive ceramic.

Satin effect

We manufacture rubber brushes with abrasive CEPIFLEX which produces a satin effect on the materials. They are less aggressive than abrasive nylon brushes producing a less textured result than the “aged effect”

News

- Grit Material for abrasives

In the realm of surface refinement, one tool reigns supreme—grit material in its abrasive or … Read more

In the realm of surface refinement, one tool reigns supreme—grit material in its abrasive or … Read more - Stock Management: Effective Strategies to Reduce Costs

Stock management plays a vital role in the logistics operations of companies, as efficient inventory … Read more

Stock management plays a vital role in the logistics operations of companies, as efficient inventory … Read more - Industry 4.0: Unlocking the Future of Manufacturing

In the ever-evolving landscape of technology, Industry 4.0 stands as a transformative force poised to … Read more

In the ever-evolving landscape of technology, Industry 4.0 stands as a transformative force poised to … Read more

Contacta con nosotros