Choosing the right resin abrasive for your project can sometimes be a daunting task. With the range of products available, it can be difficult to select the best abrasive for the job. Different types of abrasives offer different levels of effectiveness, cost and longevity. To ensure that you select the right resin abrasive for your project, you need to know how to properly assess the qualities of each abrasive and weigh the various factors to make the best decision. This guide will explain the different types of resin abrasives available, their characteristics, and how to evaluate them, so you can find the perfect one for your project.

What are resin abrasives and how do they work?

Resin abrasives are one of the most common types of abrasives used for surface finishing. They are made from a fiber or wire reinforced resin binder and are used in a wide range of industries and applications, from automotive to aerospace. They are highly prized for their high efficiency and low cost, but have a relatively short lifespan. Resin abrasives are created by combining a resin binder with abrasive minerals such as silicon carbide or aluminum oxide. The ratio of these two components determines the hardness of the abrasive; a higher proportion of resin provides a softer abrasive. As the abrasive is used, the minerals are removed, causing the abrasive to lose its hardness and become less effective. After the abrasive is used up, the remainder of the abrasive is often referred to as “fill” as it has no abrasive properties.

Different types of resin abrasives

In this section we will analyze the different types of resin abrasives available, their characteristics and applications.

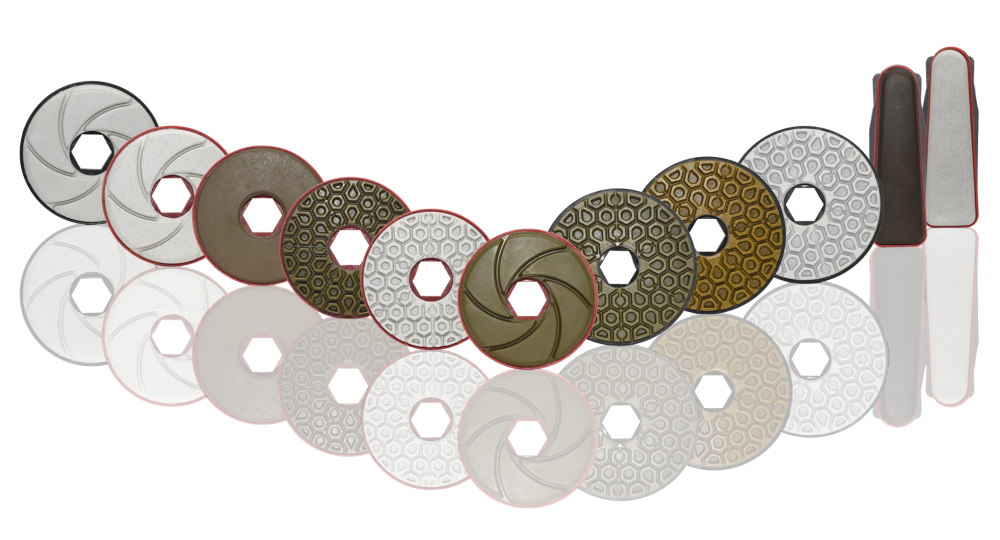

- Abrasive fickerts: Made with white resin or Epoxy, they are suitable for polishing with automatic machinery the surface of various stone slabs such as grinding granite, marble and other stones, including concrete. In addition, they have a long life and high efficiency.

- Bullnose edge polisher: The discs are perfect for adding a smooth, perfect finished edge to your countertops, steps, corners, etc. This type of molding has a smooth rounded edge, giving a clean and sophisticated finish to your tile design. Additionally, it is less prone to cracking or breaking, increasing the durability of tiled areas. The discs are available in different widths, thicknesses and qualities. Being flexible, they adapt to the shape of the piece. You can find it in white or combo resin.

- Straight edge edge polisher:suitable for making straight edge finishes. They have a long duration and impeccable quality.

- Chamfering Edges: Made of Epoxy resin it is ideal for a beveled finish.

Evaluation of the characteristics of resin abrasives

This section will discuss the characteristics of resin abrasives, such as hardness, effectiveness, cost, life, and maintenance.

- Hardness is a measure of an abrasive’s ability to remove material. Harder abrasives remove material better, but are also more expensive.

- Efficiency refers to the rate at which an abrasive removes material. The most effective abrasives are able to remove more material with less effort. Efficiency is often related to hardness, with harder abrasives being more effective.

- The cost refers to the initial investment necessary to acquire the abrasive and the cost of maintenance throughout its useful life.

- The useful life refers to the time that an abrasive will last before it needs to be replaced. Abrasives with a longer life are able to remove more material before needing to be replaced.

Tips for Choosing the Right Resin Abrasive for Your Project

Choosing the right resin abrasive for your project can sometimes be a daunting task. It is for this reason that from Cepicat we will help you at all times to resolve any possible doubts and offer you our long experience. You can contact info@cepicat.com, and we will be happy to help you.